|

|

Definition of Operational Time

Operational time is the period during which a work operation is performed, involving a change in the shape, properties, or quality of the object of work,

its position in space, or other changes provided for by the technology of its processing.

Operational time is the time spent directly on performing a given job (operation), repeated for each unit of production, batch, or volume of work.

Operational time is the time spent on direct processing of the product, as well as installation/removal of the part, measuring operations, and other operations

provided for by the technology of its manufacture.

This term is used for standardization of labor and individual work operations. Operational time is a part of the piece time for performing a technological

operation, during which useful work is directly performed, for example, on processing a part.

During standardization of an operation, the rater first, according to the technological process, calculates the necessary time for processing the part, then

takes into account the time required to perform auxiliary operations. Auxiliary operations include the time spent on installing and removing a part,

measuring it, operating equipment, etc. The sum of the obtained values will constitute the operational time of the technological operation.

Formula for Determining Operational Time

Operational time consists of main and auxiliary time. Operational time is equal to the sum of the main and auxiliary time for performing a work operation:

where:

-

Tmain - time spent on directly performing part processing operations

-

Taux - time spent on performing mandatory operations that do not directly change the subject of labor but are necessary for performing

the operation (installation, removal, measurement, control, management)

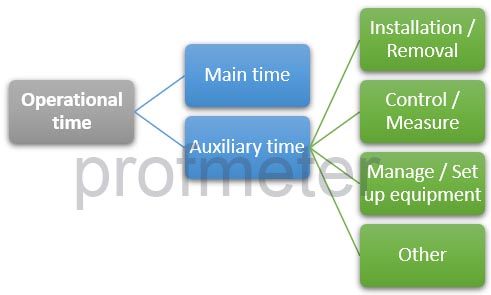

Structure of Operational Time

Operational time can be broken down into the following components:

-

Main Time: The time spent on the primary operations that directly change the shape, properties, or quality of the object of work.

-

Auxiliary Time: The time spent on necessary but non-transformative operations, such as setting up equipment, measuring, and controlling the process.

Methods for Calculating Operational Time

The operational time for processing a part is determined by the following main methods:

-

Analytical Method: Standardization by the analytical method requires high qualification of the rate setter, understanding of the production technology,

and the ability to determine the most rational sequence for performing technological operations.

To obtain reliable and adequate results when standardizing using the analytical method, the technological process must meet the following conditions:

-

Stability of the Process: The results of the worker performing the same actions should lead to the same results and states of the object of labor.

The object of labor should be predictably subject to planned changes, and the time of transformation should be stable and predictable.

-

Stability of the Sequence of Operations: The required sequence of operations, their nomenclature, and duration should be stable.

Examples of operations whose operational time is well standardized using the analytical method include assembly on a conveyor and processing of

a part on a semi-automatic machine.

-

Timing Method: When conducting timing of the execution of a technological operation, it is necessary to take into account that the worker performing

the operation may not always be interested in the objective receipt of data by the observer. The worker may perform the operation more slowly than

usual or add unnecessary stages or transitions to their actions.

The main method of "fighting" against obtaining unreliable data using timekeeping is to exclude from the statistical sample the results obtained at the

very beginning of the observation process. After a certain number of repetitions of the same operation, the worker will stop consciously controlling and

slowing down their actions.

-

Combined Method: The combined method integrates both the analytical method and timing to achieve the most accurate results.

Wage Fund Management |

Описание курса

| Current assets

|